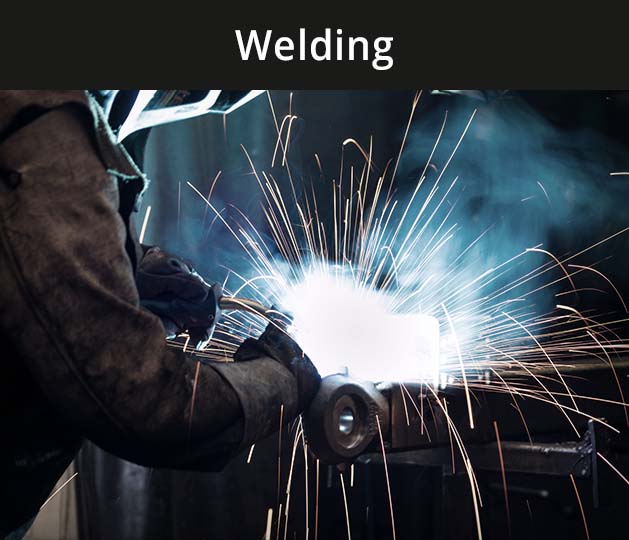

Welding

We use electric arc and flame welding in production. These are mainly MIG, MAG and TIG methods as well as resistance welding. To meet the qualitative and quantitative requirements of our customers, we use robotic, semi-automatic and manual welding.

Possibility of combination of laser, plasma, flame, blasting, sandblasting, CNC bending, pressing.

After welding we blast or sandblast the weldments. We can provide surface treatment of products after welding with long-term certified partners. We use both galvanizing and hot dip galvanizing on our products. For painting we use powder, synthetic paints or KTL cataphoretic painting. For the refinement of materials we use technologies such as hardening, heat treating, blackening.

Welding is carried out with welding sources from Cloos. With robotic welding, we can weld a weldment with maximum dimensions of 1 000 x 2 300 mm and a maximum load of 300 kg.