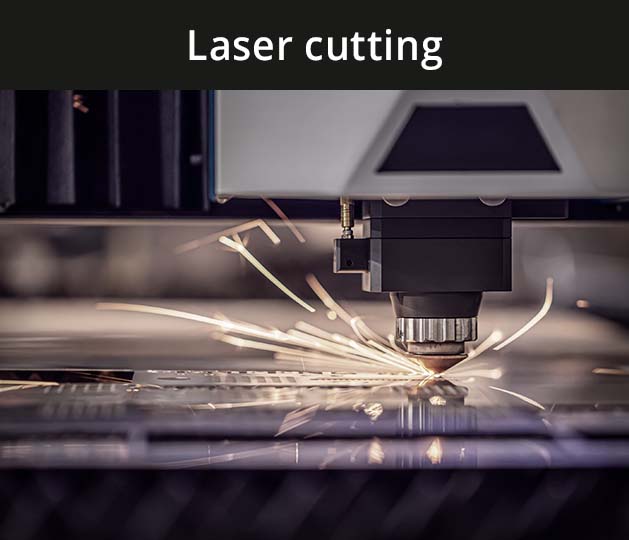

Laser cutting

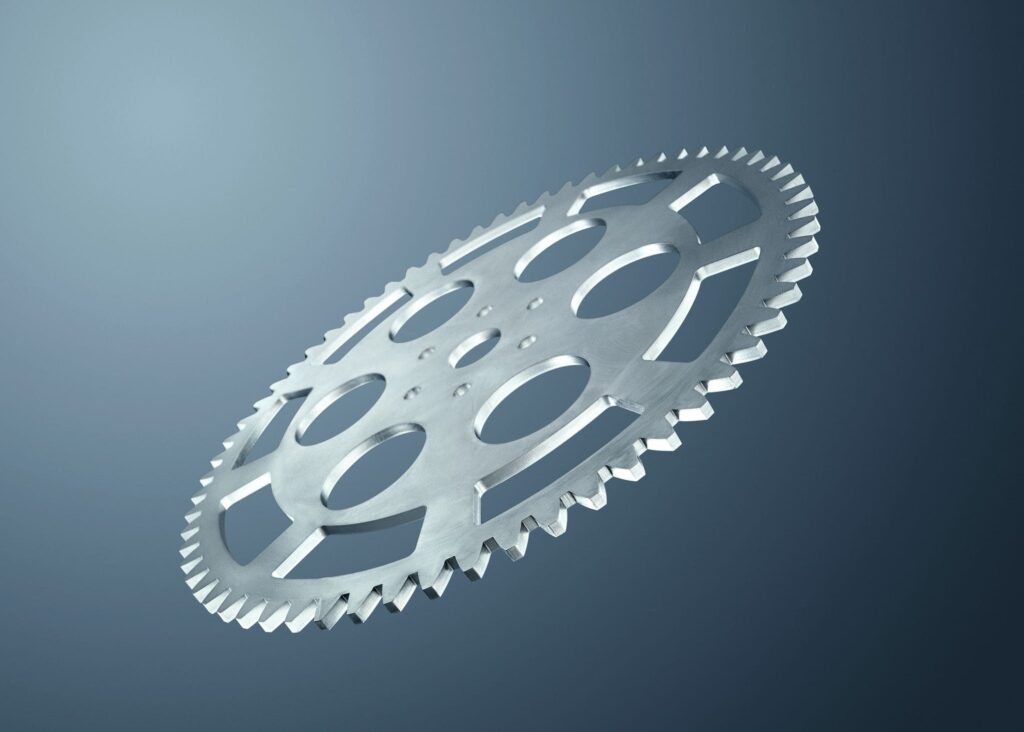

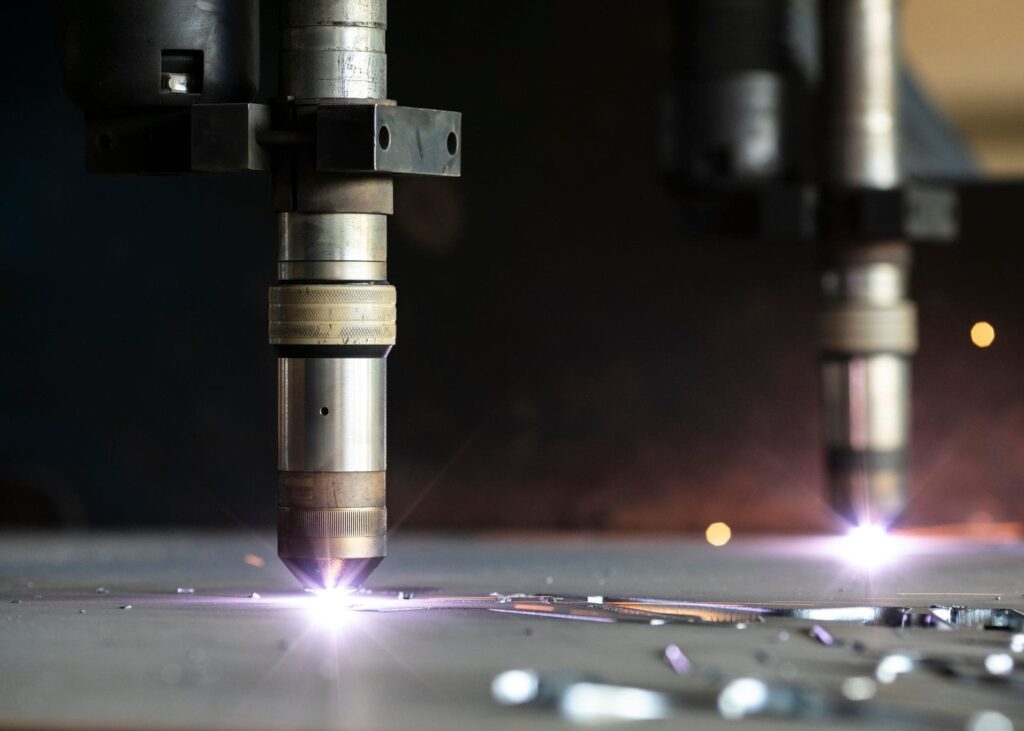

We cut sheet metal with Trumpf lasers, Omnicut plasma cutting machine and Cortina flame cutting machine. We provide cutting of tubes and square profiles with the Trumpf Tube laser.

The maximum material thickness for cutting with the help of oxygen is 100 mm and the maximum sheet size is 1 800 × 4 000 mm. The maximum material thickness for cutting with plasma is 20 mm and the maximum sheet size is 2 000 × 6 000 mm.

Cutting with Trulaser 5030 the maximum sheet size is 2 000 x 4 000 mm, the maximum thickness for cutting steel is 20 mm, the maximum thickness for cutting stainless steel is 12 mm, the maximum thickness for cutting aluminium is 12 mm.

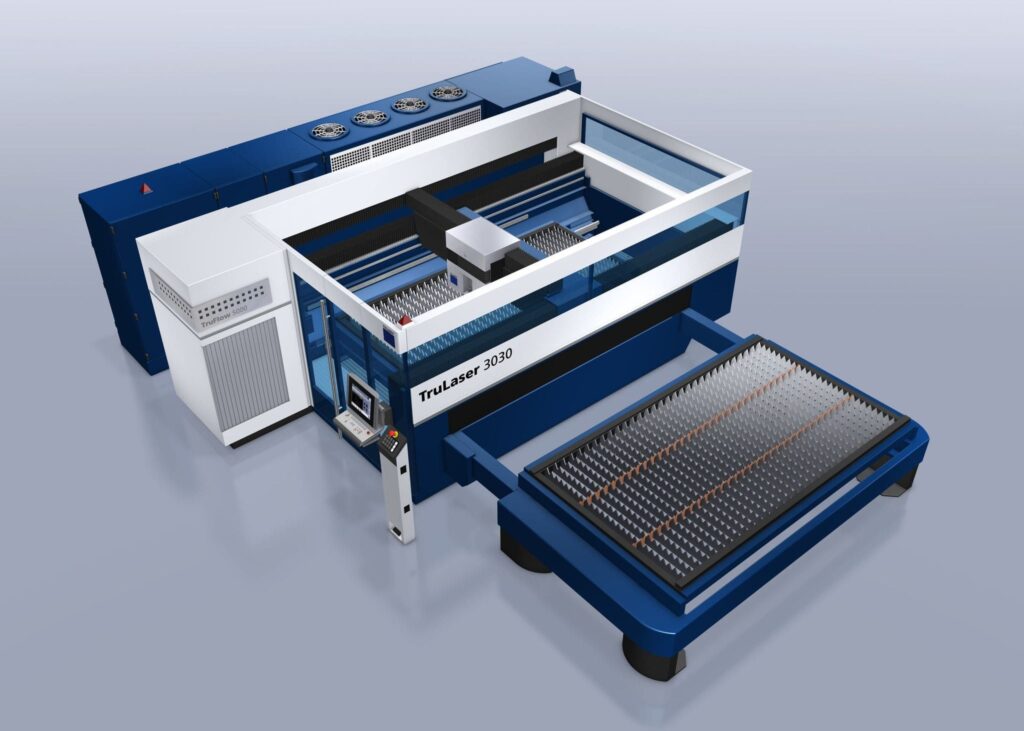

Cutting with Trulaser 3030 the maximum sheet size is 1 500 x 3 000 mm, the maximum thickness when cutting steel is 20 mm, the maximum thickness when cutting stainless steel is 12 mm, the maximum thickness when cutting aluminium is 12 mm.

Cutting of tube profiles is provided by the TruLaser Tube 5000 laser, where the maximum length of the input material is 6 000 mm, the maximum length of the component is 3 000 mm, the maximum diameter of the tube is 150 mm, the maximum width of the tube is 100 x 100 mm and the maximum wall thickness is 8 mm.

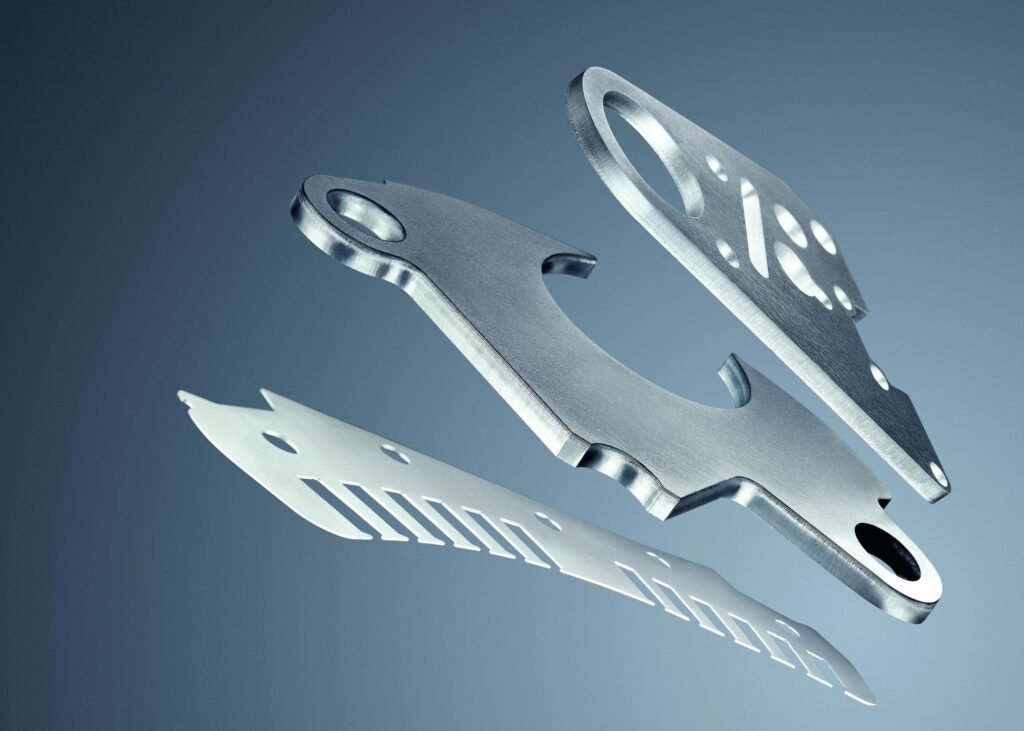

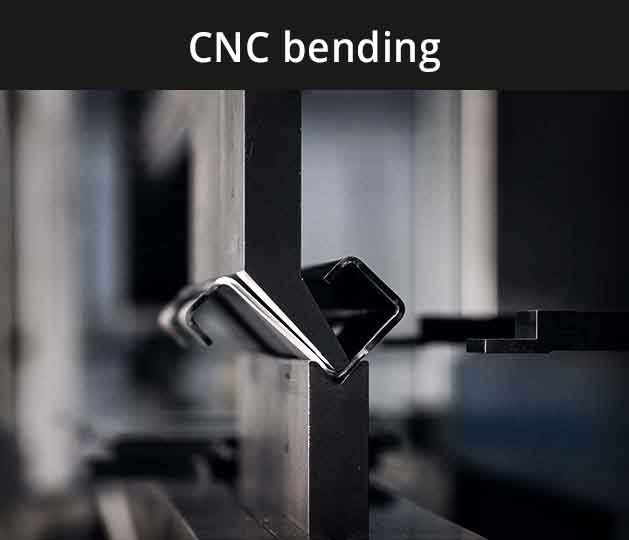

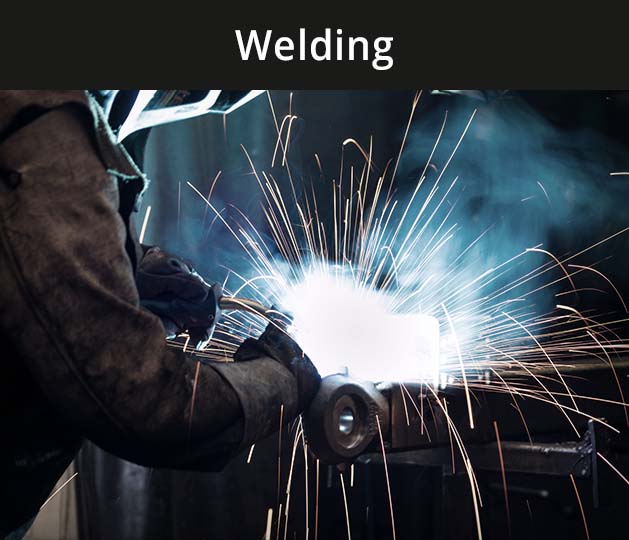

After cutting, we can arrange bending with CNC bending machine, surface treatment as well as heat treatment of products with long-term certified partners. We use both galvanizing and hot dip galvanizing on our products. For colouring we use powder, synthetic paints or KTL cataphoretic painting. For the refinement of materials we use technologies such as hardening, heat treating, blackening.

Under one roof, parts can cut by laser, plasma or flame, we sandblast and then bend them as required.