Pressing and stamping

We actively use more than 40 eccentric presses from 10 to 400 tons and 3 hydraulic presses. The maximum length of the pressing tool is 1 000 mm and the width 700 mm.

The operation of the press shop is closely connected with the tool and assembly department. This is particularly suitable when developing tools for the production of new goods. We are able to deal operatively with individual customer requirements and at the same time produce goods with tools provided by our customers.

We produce moldings from sheet metal as well as rolls. We process rolls in lines, which are equipped with unwinders and straighteners, where the maximum weight of the roll is 1,5 tons. On these lines we process rolling with a width of up to 300 mm and a thickness of up to 5 mm.

After molding, it is possible to deburr the parts with a grinding machine.

According to the requirements after pressing, we can arrange the surface treatment of the products with long-term certified partners. We use both galvanizing and hot dip galvanizing on our products. For painting we use powder, synthetic paints or KTL cataphoretic painting. For the refinement of materials we use technologies such as hardening, heat treating, blackening.

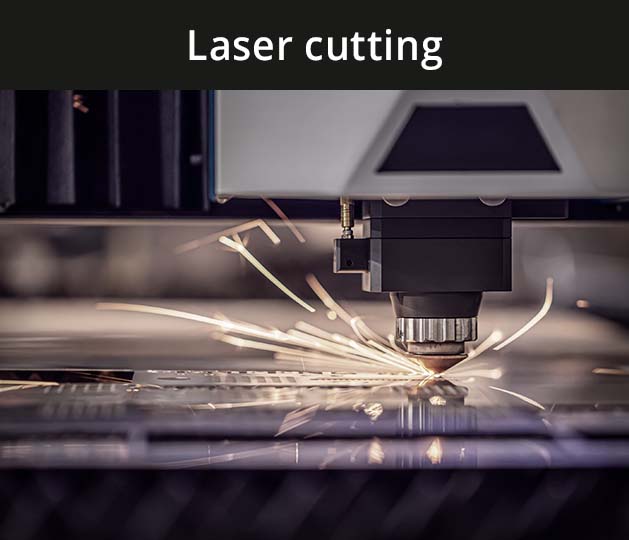

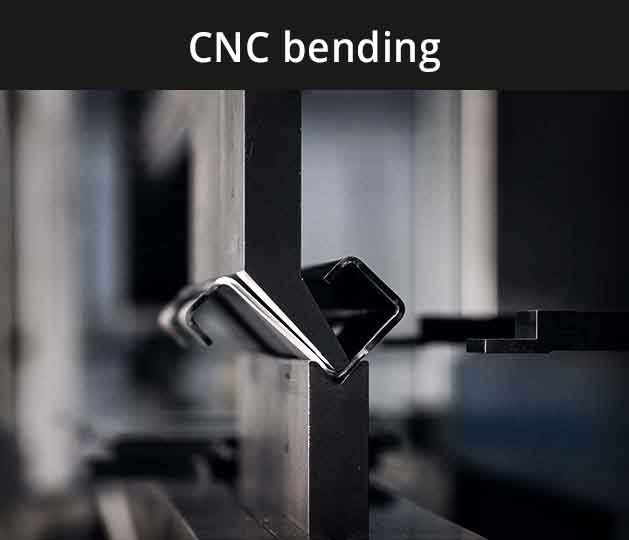

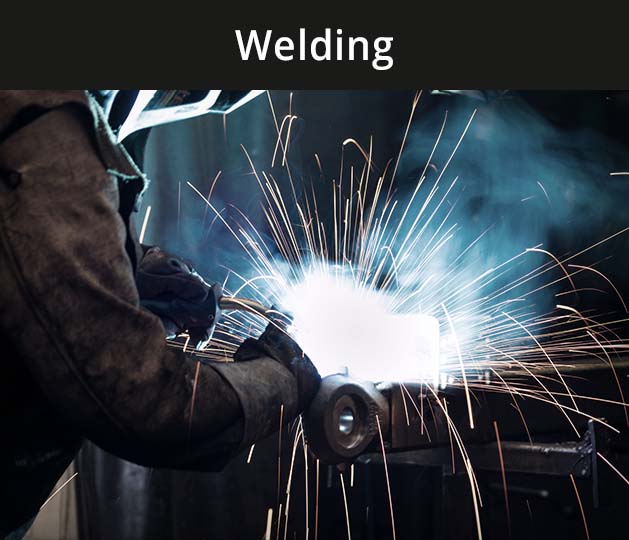

A combination of laser cutting, pressing, grinding, bending and welding is possible.